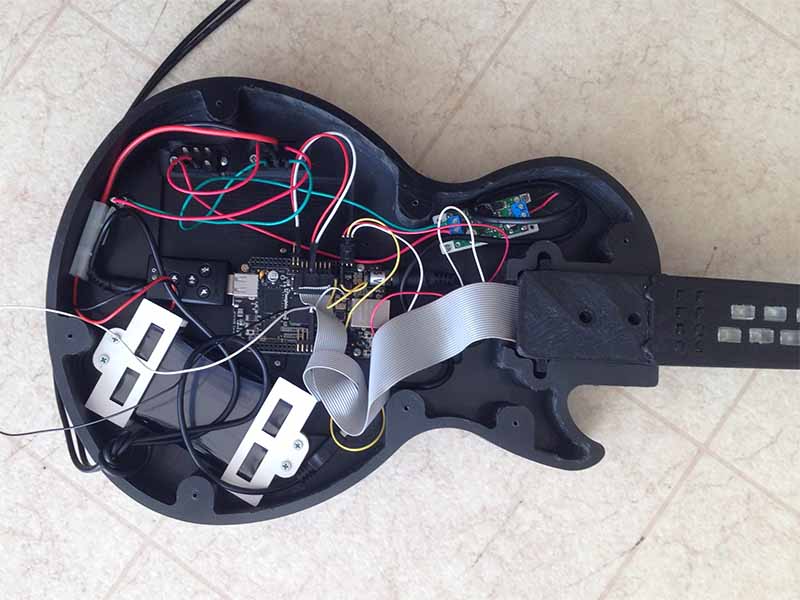

We can prototype complex inventions.

We machine custom parts from various materials, including steel, aluminum, plastic, and wood.

With all this capability in-house, we design and prototype products that typically require larger, expensive teams.

From DC to stepper motors, we have done it all.

Simple one-component inventions can quickly be designed and prototyped.

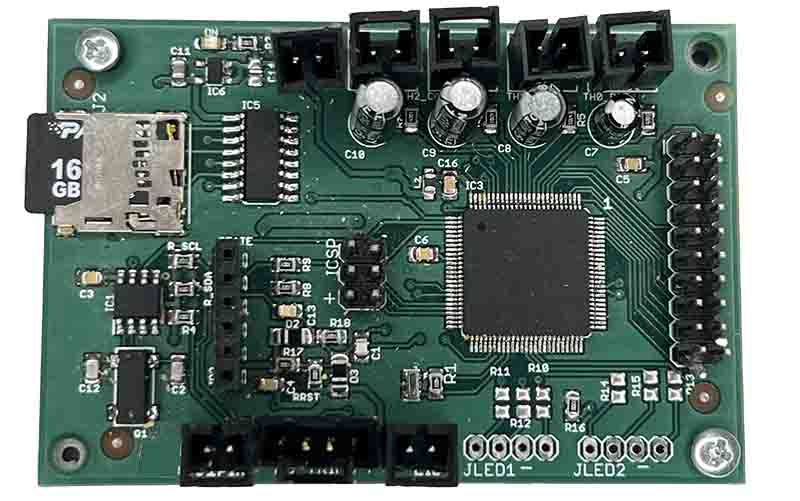

We use a domestic supplier for our prototype PCBs to save time. We assemble our printed circuit boards in-house.